U.S. Department of Labor backs RCBI workforce initiative

$1.49 million award

RCBI and a broad coalition of partners, including Marshall University’s Creating Opportunities for Recovery Employment (CORE), Region 1, 2 and 3 Workforce Boards in West Virginia, the Greater Ohio Workforce Board, Mountwest Community and Technical College, Rhema Development and Hope Nation as well as private industry partners will launch an innovative, mutifaceted, industry-driven workforce training initiative across the Tri-State region thanks to a $1.49 million grant from the U.S. Department of Labor.

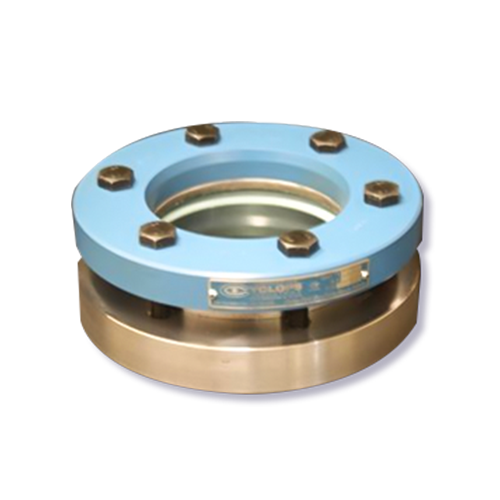

The Advanced Manufacturing and Construction Skills Training initiative will provide the hands-on education and training needed to put people to work, said Charlotte Weber, RCBI director & CEO. The program will target and retrain workers displaced because of the downturn in this traditionally coal-reliant region as well as individuals recovering from substance use disorders.

As part of the initiative, RCBI will expand the short-term manufacturing training and career skills degree and certificate programs it offers in partnership with Mountwest to train manufacturing technicians for entry level jobs that align with the specific needs of industry. In addition, Mountwest will expand its industrial electronics offerings and provide peer recovery counseling through the Southern West Virginia Collegiate Peer Recovery Network.

The initiative also will team with the soon-to-launch Marshall/Mountwest Aviation Maintenance Technology program to offer additional certifications that not only will enhance students’ aviation education but develop skill sets applicable across a variety of industries.

Through an innovative partnership with Rhema Development and Hope Nation, individuals will be given the opportunity for immediate employment in construction while they learn to build components for prefabricated housing units. Marshall’s CORE program will conduct training for recovering individuals as well as industry human resources teams to assist with employment re-entry for individuals completing the training programs.

“This effort will build upon RCBI’s successful, broad-based workforce development initiatives by leveraging the considerable resources of our multiple partners to deliver flexible, industry-driven training that leads to sustainable employment for participants,” Weber said. “RCBI appreciates the recognition and support provided by the U.S. Department of Labor and the Appalachian Regional Commission.”

The service area will include Boone, Cabell, Kanawha, Lincoln, Logan, McDowell, Mingo, Putnam and Wayne counties in West Virginia; Boyd, Carter, Greenup and Lawrence counties in Kentucky; and Lawrence County in Ohio.

The initiative is funded through the Workforce Opportunity for Rural Communities Initiative, a joint project of the U.S. Department of Labor and the Appalachian Regional Commission to align workforce development efforts with existing economic development strategies in rural communities hard hit by economic transition.

To learn more about the workforce training options available through the program, contact RCBI’s Carol Howerton at carol.howerton@rcbi.org or 304.781.1680.